Operational Technology (OT) is combination of hardware and software that manages, controls and monitors the physical devices and Industry processes. An industry either extracts raw materials (Primary Industry Sector) or manufacturing goods (Secondary Industry Sector) or provide services (Tertiary Industry Sector). Each industry has it’s own set of unique physical equipments and machinery that should be operated and orchestrated. The industry manufacturing process has evolved across years from manual labor to machinery to smart computing machines through Industry Revolutions. The Operational Technology is the infrastructure that manages the industry infrastructure end to end.

Industrial Control System (ICS)

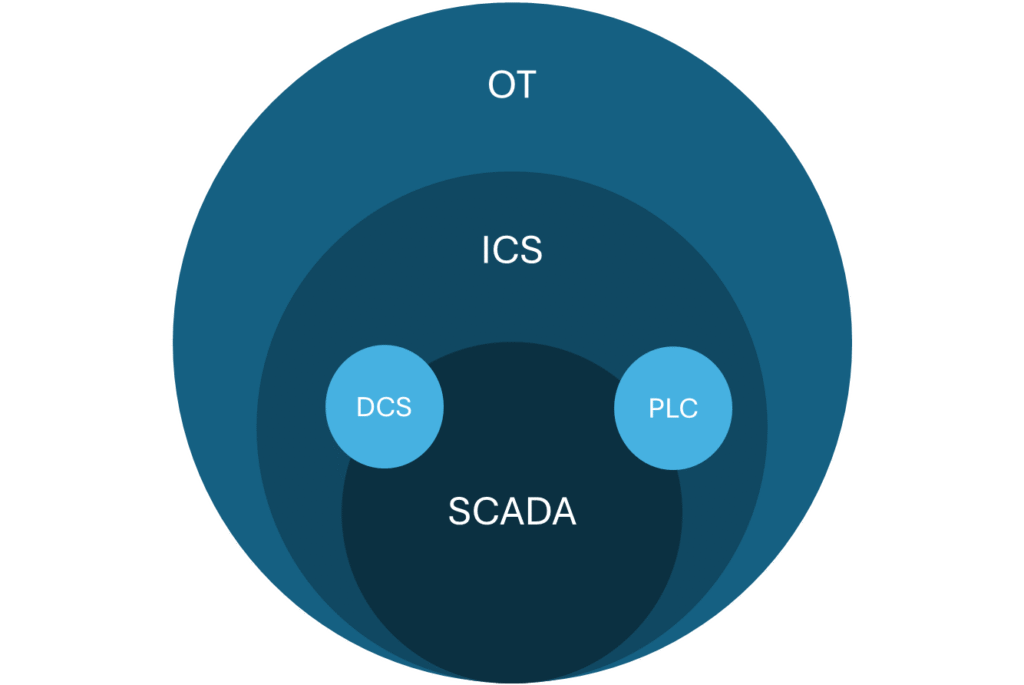

OT is the broader category of hardware and software that controls and monitor industry processes and operations. ICS is part of OT that controls and automates the industry processes.

The Industry Control System (ICS) is the control system that controls the processes of a manufacturing infrastructure using automation and orchestration. ICS is collection of devices connected through networks controlled using a control loop. A control loop is the fundamental building block of a control system. The components of a control loop are as follows:

Sensor is the component that measures the state of the process variable and sends it to the Controller.

Controller is the component that has the desired set value. It receives the measurement value from the sensor and makes the decision.

Actuator gets the instruction from the controller and takes the action on the physical equipment in the infrastructure.

The control system operates in the following three modes:

Open Loop – The output of the system depends on pre-configured data.

Closed Loop – The output of the system depends on the feedback.

Manual Loop – The output of the system depends on manual settings.

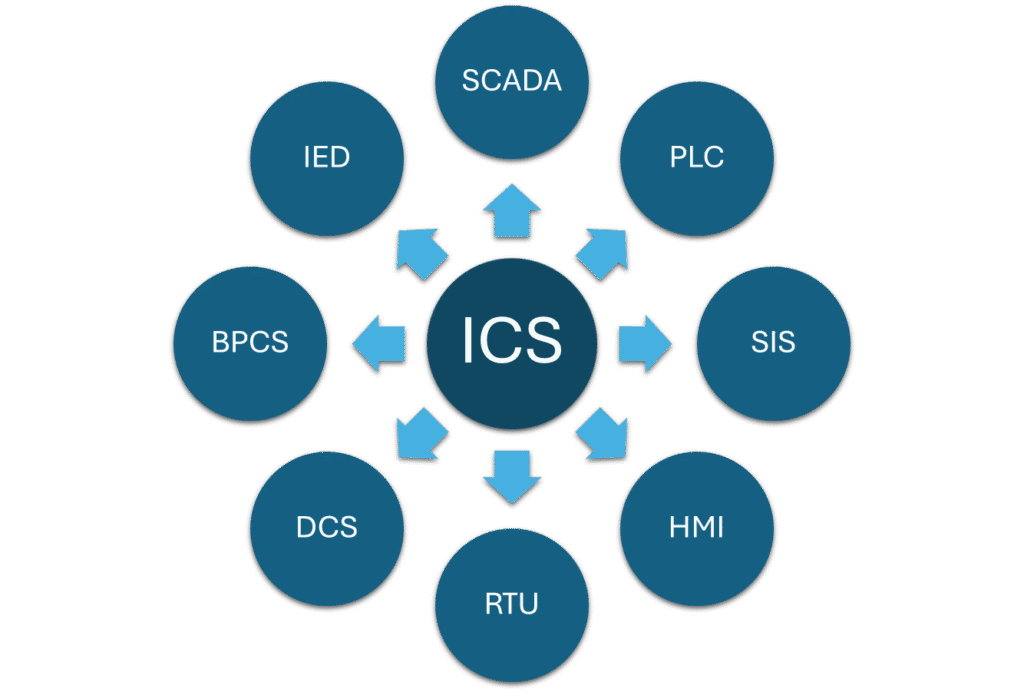

Components of ICS

ICS compromises multiple components within to perform the industry operations as following:

Supervisory Control and Data Acquisition (SCADA) is a centralized supervisory control system that manages and controls the industry infrastructure and operations. Generally SCADA is distributed across wide geographical area.

Basic Process Control System (BPCS) is a complete computer system that monitors and controls industry processes.

DCS (Distributed Control System) is the control system that manages the monitors and manages an industry’s facility or plants. It is the technology that implements the BPCS.

Programmable Logic Controller (PLC) is an industrial computer that manages and controls equipments using programs.

Human-Machine Interface (HMI) is the user interface through which the operators connect and manages the equipments.

Remote Terminal Unit (RTU) is microprocessor-based electronic device that connects the physical equipments of the industry plant to the DCS.

Intelligent Electronic Device (IED) is an embedded microprocessor device that has processing capability for managing and controlling equipments.

Safety Instrumented Systems (SIS) is an automated control system designed to protect the manufacturing infrastructure during any hazardous incident in the industry.